SURFACE GRINDER

DSG-3A1224.3A1224H SEMI-AUTO SADDLE SURFACE GRINDER

DSG-3A1224.3A1224H

| DESCRIPTION | UNIT | 3A1224 | 3A1224H | |||||

|---|---|---|---|---|---|---|---|---|

| General Capacity | Table size (lxw) | mm | 300x600 | |||||

| Max.grinding length | mm | 650 | ||||||

| Max.grinding width | mm | 340 | ||||||

| Distance from table surface to spindle center | mm | 600/700(opt.) | ||||||

| Standard mag. Chuck size | mm | 300x600 | ||||||

| Longitudinal Movement | Manual travel | mm | 700 | |||||

| Hydraulic traverse | mm | 650 | ||||||

| Hydraulic feed (table speed) approx. | m/min | 1~19 | ||||||

| Cross Movement | Manual travel | mm | 340 | |||||

| Auto cross feed | mm | 310 | ||||||

| Hand feed per revolution | mm | 5 | ||||||

| Hand feed per graduation | mm | 0.02 | ||||||

| Continuous cross feed (approx.)50/60HZ | mm/min | 1100 | ||||||

| Increment cross feed | mm/min | 1~20 | ||||||

| Vertical Downfeed | Rapid traverse (approx.) | mm/min | 800 | |||||

| Hand feed per revolution | mm | 1mm | ||||||

| Hand feed per graduation | mm | 0.005mm | ||||||

| Manual pulse generator |

|

x1,x5x10 |

||||||

| Grinding Wheel | Wheel size (diax width xbore) | mm | Ø355x38x127 | |||||

| Spindle speed (50/60HZ) | r.p.m | 1450/1750 | ||||||

| Motor | Spindle drive motor | HP | 5/7.5(opt.) | |||||

| Hydraulic motor | HP | 2 | ||||||

| Cross feed motor | W | 80 | ||||||

| Elevating motor | W | 80 | ||||||

| Rapid hand elevatipn servo motor | W | 400 | ||||||

| Weight | Net weight / gross weight (approx.) | kg | 2350/2550 | |||||

| Packing Size | Length × width × height | mm | 2400x1900x2280 | |||||

※ The manufacturer reserves right to modify the design,specification mechanisms etc. without notice.

- Grinding wheel

- Wheel flange with extractor

- Balancing arbor

- Diamond dresser and base

- Working lamp

- Leveling plate

- Leveling screw & nut

- Tool box with tools

- Operation manual & Inspection report

- Touch-up paint

- Machine structure is manufactured from high quality Meehanite class FC cast iron

- Spindle motor select high stability Siemens motor

- Saddle guide way use double V designed, coated with Turcite-B and hand-scraped provide smooth movement,

-

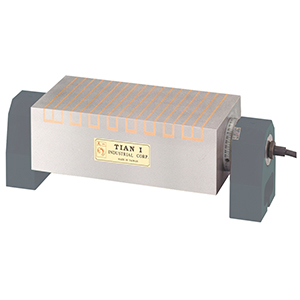

Permanent magnetic chuck

Permanent magnetic chuck -

Electro magnetic chuck

Electro magnetic chuck -

Demagnetizer

Demagnetizer -

Inclinable permanent mag. Chuck

Inclinable permanent mag. Chuck -

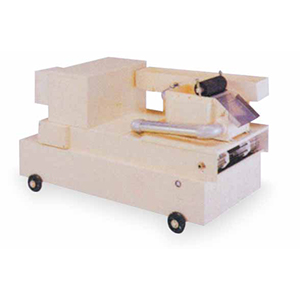

Coolant & Dust unit

Coolant & Dust unit -

Magnetic separator and coolant system

Magnetic separator and coolant system -

Auto.Paper Strip Filter

Auto.Paper Strip Filter -

Auto. Paper strip fiter with magentic separator and coolant system

Auto. Paper strip fiter with magentic separator and coolant system -

Inverter

Inverter -

Demagnetizer

Demagnetizer -

Digital readout

Digital readout -

On line wheel balance system(Manual)

On line wheel balance system(Manual) -

Flange

Flange -

Manual overhead dresser

Manual overhead dresser