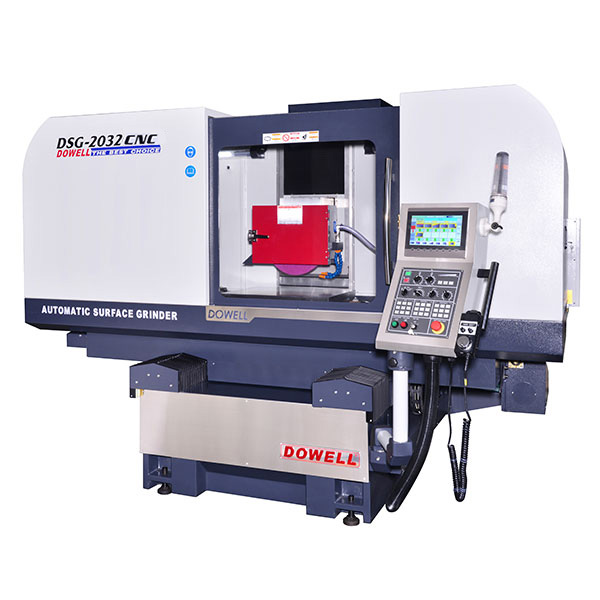

NC/CNC SURFACE GRINDER

DSG-2032CNC NC/CNC SURFACE GRINDER

DSG-2032CNC

Control system

-

MITSUBISH (STD.)

MITSUBISH (STD.) -

FANUC / (OPT.)

FANUC / (OPT.)

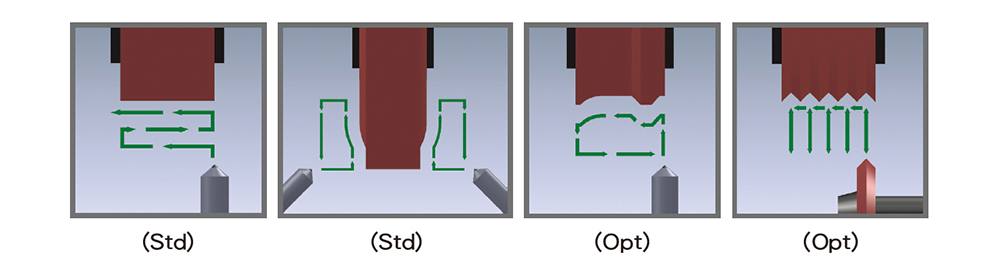

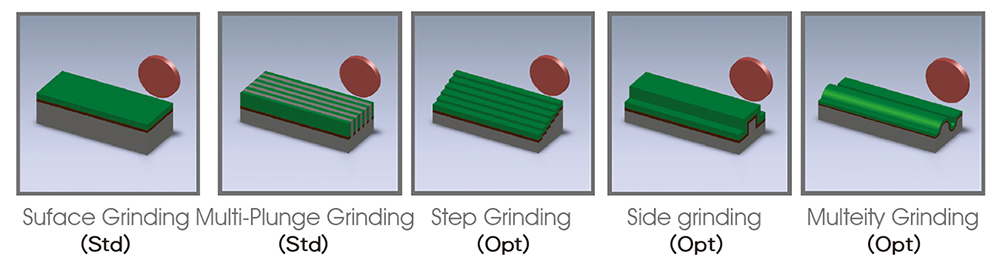

Dressing Select

Grinding Select

| DESCRIPTION | UNIT | DSG-2032CNC | |

|---|---|---|---|

| General Capacity | Table size (L x W) | mm | 800x500 |

| Distance from table surface to spindle center | mm | 680 | |

| Longitudinal Movement |

Hydraulic feed (table speed )approx | m/min | 5~25 |

| Servo motor feed (table speed )approx | m/min | 1~15 | |

| Belt feed(table speed) approx | m/min | 1~23 | |

| Cross Movement | Increment cross feed | mm/min | 1000 |

| (M.P.G) | mm | X1:0.001 X5:0.005 X10:0.1 |

|

| Vertical Downfeed | Increment cross feed | mm/min | 1000 |

| (M.P.G) | mm | X1:0.001 X5:0.005 X10:0.1 |

|

| Grinding Wheel | Wheel size (Dia x Width x Bore) | mm | 405×50×127 |

| Spindle speed (50/60HZ) | r.p.m. | 1450/1750 | |

| Motors | Spindle drive motor | HP | 15 |

| Hydraulic motor | HP | 5 | |

| Y servo motor | KW | 1 | |

| Z servo motor | KW | 1 | |

| X servo motor (opt.) | KW | 2 | |

| Weight | Net weight/gross weight (approx.) | kg | 5500/6200 |

| Packing Size | Length x Width x Height | cm | 400×228×228 |

※ The manufacturer reserves right to modify the design,specification mechanisms etc. without notice.

- “MEEHANITE” casting. stability.

- Machine base fully supported design creating high rigidity structure.

- 3 axis uses high precision ballscrew AC servo motor drive.

- X axis use double V guide way design and driven by hydraulic

- Y 、 Z axis uses high stiffness and rigidity linear roller guideways.

- High precision spindle.

- Closure type water-proof guard.

-

Magnetic Filter

Magnetic Filter -

Auto paper strip filter with magnetic separator and coolant system

Auto paper strip filter with magnetic separator and coolant system -

Oil mist collector

Oil mist collector -

Air-Conditioner

Air-Conditioner -

Inverter

Inverter -

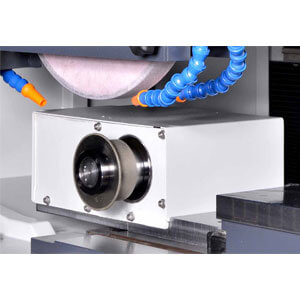

On line wheel balance system (manual)

On line wheel balance system (manual) -

On line wheel balance system (auto)

On line wheel balance system (auto) -

Digital readout

Digital readout -

CNC rotary table

CNC rotary table -

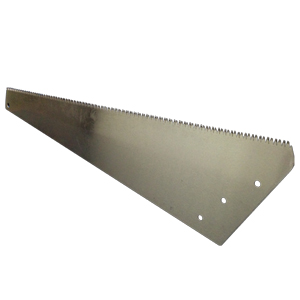

Roller dresser

Roller dresser