ROTARY SURFACE GRINDER

HR-400AND HORIZONTAL ROTARY SURFACE GRINDER

HR-400AND

| DESCRIPTION | UNIT | HR-400AND |

|---|---|---|

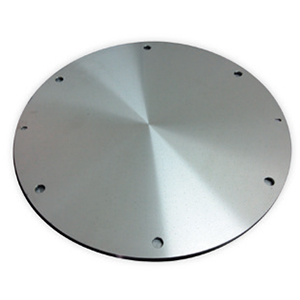

| Rotary magnetic chuck dia. | mm | 400 |

| Maxi grinding radius | mm | 225 |

| Distance of table surface to spindle surface center | mm | 450 |

| Rotary magnetic chuck speed | r.p.m. | 20~250 |

| Rotary magnetic chuck horse power | kw | 1.5 |

| Spindle motor | HP | 5 |

| Spindle speed (50/60Hz) | r.p.m. | 1450/1750 |

| Auto downfeed horse power | W | Servo Motor 500 |

| Vertical hand wheel downfeed per revolution | MPG/mm | x1, x5, x10 / 0.1, 0.5, 1 |

| Vertical hand wheel downfeed per graduation | MPG/mm | x1, x5, x10 / 0.001, 0.005, 0.01 |

| Wheel size (dia x width x bore) | mm | 355x38x127 |

| Net weight / gross weight (approx) | kg | 3200/3800 |

| Packing size (LxWxH) | mm | 2400x1900x2100 |

※ The manufacturer reserves right to modify the design,specification mechanisms etc. without notice.

-

Si

Si -

Quariz

Quariz -

Ceramics

Ceramics -

Ceramics Ring

Ceramics Ring -

Retaining Ring

Retaining Ring -

Slitting Saws

Slitting Saws -

Slitter Knife

Slitter Knife -

Spindle parts

Spindle parts -

- Meehanite Class FC 30 casting with slide way provides high stiffness and wear resistance maintaining the accuracy of the machine.

- Spindle lateral design creates stability during heavy cutting.

- Spindle Siemens V3 Grade motor provides good water proofing resisting moisture.

- Vertical feeding uses 3 high stiffness and rigidity linear roller guides allowing smoothly vertical feeding whilst maintaining high stiffness.

- Small workpiece suction is accomplished by fine electrical magnetic chuck.

-

Coolant system

Coolant system -

Magnetic filter

Magnetic filter -

Auto. paper strip filter with magnetic separator and coolant system

Auto. paper strip filter with magnetic separator and coolant system -

Oil mist collector

Oil mist collector -

Demagnetizer

Demagnetizer -

On line wheel balance system (Manual)

On line wheel balance system (Manual) -

SBS (Auto)

SBS (Auto) -

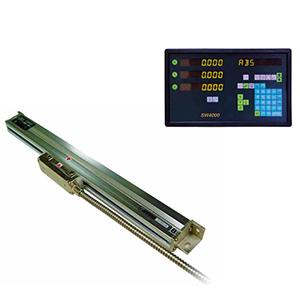

Digital readout

Digital readout -

Inverter

Inverter -

Air-Conditioner

Air-Conditioner